Glass chemical tempering

1/Reasons and advantages for glass chemical tempering

The chemical tempering is used when the thermal tempering meets limits.

Small glass thickness

Even if some suppliers offer now machines able to temper 2 mm thickness glass, the chemical tempering in this case give better results.

Curved glass

The chemical tempering is done with a temperature around 400°C which don’t change the glass geometrical shape

This is particularly important when the curved glass has to be laminated after tempering.

The optical quality

Chemical tempering gives better result than thermal tempering when a high optical quality is required.

When a more important hardness is required than the one the thermal tempering can supply.

With the chemical tempering it is possible to increase with a factor 4 the hardness in touch with the thermal tempering.

No surface distorsions

With chemical tempering you do not have surface distortion

Processing after tempering

One of the advantages for chemical tempering is that you can process the glass (drilling, edging, polishing, sandblasting, cutting…) after tempering. This is not possible for thermal tempering.

On another side with chemical tempering it is more difficult or even impossible to temper very large glasses, because the maximum furnaces dimensions (around 3200x2200).

More important in case the glass breaks, they remain very dangerous large glass pieces. For this reason, only glasses coming from thermal tempering can be accepted as “safety glasses”

2/Glass thermal tempering characteristics

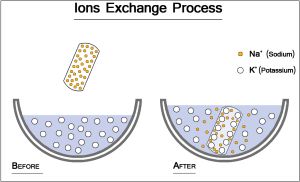

The idea for chemical tempering (like for thermal tempering) is to put the glass surface under compression to increase strongly the hardness. In the chemical tempering case it is obtained by the migration at the glass surface (between 20 and 100 micrometers) of big potassium cations which take the cations sodium place. Sodium and calcium having similar chemical characteristics this change does not modify the glass properties.

This change is done dropping the glass inside a potassium salt bath between 12 and 20 hours. The salt bath temperature is around 400° Celcius.

3/Comparison between thermal and chemical tempering

|

|

Thermal tempering |

Chemical tempering |

|

Thickness (mm) |

3 à 19 |

0.5 à 19 |

|

Surface compression ( N/mq) |

30/70 |

300/400 |

|

Thickness for the compressed area |

20% from the glass total thickness |

20 to 120 microns |

|

Flexion resistance ( N/mq) |

120/200 |

250/600 |

|

Pieces dimensions when glass breaks |

Small pieces |

Large pieces |

|

Processing after tempering

|

No

|

Yes (cutting, drilling, edging, polishing, sandblasting…) |

4/The main chemical markets

The cost for chemical tempering is much more important than the one for thermal tempering. So the main markets for chemical tempering are where the thermal tempering meets limits or problems.

-Small thickness

-Quality (distortion, optical quality, hardness..)

The markets for chemical tempering is in aviation, space and naval industry, automotive industry, luxury, architectural (bending) and in general when you need nos distortion.

5/Conclusion

Chemical tempering is another way to glass tempering, mainly when thermal tempering can bring a proper solution. But to be able to reach the quality required chemical tempering must be done in automatized furnaces and with security and checking systems to supply with productivity the high quality level required.