Newletters verre

Flat glass and mirrors newsletter. September 2016.

Very strong growth in Internet sales of wheels for mirrors machines.

Vedip, the first European site (French origin) Internet sales of Italian wheels for mirrors machines saw its revenues for the third quarter 2016 increased more than 2.

The strategy developed by Vedip to propose, in partnership with a leading Italian manufacturers of wheels for mirrors, very competitive prices for working only on the Internet, detailed fact sheets with photos, standard wheels made by manufacturers / Machines / Positions, alternative wheels and a telephone support seems to meet the needs of the market in Europe mirrors.

The site already has 861 tools now online continue to improve the technical data of the tools and the number of referenced machinery (over a hundred).

On Vedip you can view the data sheets (with photos and price) of the wheels for the main flat glass processing machines of the market (straight line edging machines, CNC, drills, double edger, chamfering ...) and the most important suppliers (Intermac, Bovone, Glaston, Bavelloni, Lattuada, Schiatti, JANBAC Baudin, Battelino, Denver, Bimatech, Ada, Besana, Bottero ....).

www.vedip.com

Contact : This e-mail address is being protected from spambots. You need JavaScript enabled to view it

Tel 00 33 782 39 43 34.

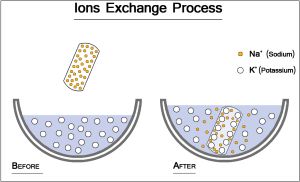

Chemical tempering. Technical data

|

Kind of treatment |

Annealing |

Hardened |

Thermical tempering |

Chemical tempering |

|

Glass theackness |

2.3 à 19 mm |

2.3 à 8 mm |

3 à 19 mm |

0.7 à 19 mm |

|

Compression N/mq |

0 |

30 à 70 |

30 à 70 |

300 à 400 |

|

Area treated thikness |

0% |

20 % of total thickness |

20 % of total thickness |

Up to 100/ 200 microns |

|

Fragments |

Big fragments |

Middle sizes fragments |

Small fragments |

Middle sizes fragments |

Dates for next Glasstec

The next Glasstec show, will take place in Dysseldorf from 23 to 26 october 2018. 1235 exhibitors and more than 40 000 visitors have been present during the last 2016 show.

Glasstronic acquisition

On September 1st LiSEC’s acquisition of Glastronic (Hungary), part of the Jüllich Group took place.

As a part of the LiSEC Group, Glastronic will in the future acquire used LiSEC machines, overhaul them according to the customers’ requirements and resell them. Dr. Anita Panowitz (Administration, Production, IT) and Bernhard Scheidl (Purchasing, Sales, Engineering) will manage the new company together. Bernhard Scheidl: ”Worldwide, LiSEC has a very large installed basis of plants and machines – the potential is therefore enormous. We will now proactively address the purchase and sale of used LiSEC machines and we are glad to have found a partner with Glastronic who is experienced in machines for the processing and machining of flat glass.”

Next Vitrum show

The next Vitrum show, will take place in Milan from 3 to 6 october 2017. 247 exhibitors and more than 19 000 visitors have been present during the last 2015 show.

Glassbuild America 2016

The flat glass show will take place in Las Vegas from 19 to 21 October 2016 with more than 430 exhibitors.

Fusing SCHOOL

28, 29 and 30 October.

Discover the technique of fusing that uses the reactions of glass heated to high temperatures to gather multiple pieces of different colors in one piece. The compositions thus obtained are then shaped by thermoforming to create custom objects.

Registration deadline until October 15

Registration with the Swiss School of Stained Glass & Creation or from our website http://ecolevitrail.com/

New position for Richard Bazin

After been Glaston France manager and Lisec France manager, Richard Bazin manages now the Landglass activities in France.

New company for Cathy Paulino

Cathy Paulino who was sales manager for Albat is now Sales Manager South West Europe for Synerglass Soft

Lisec buys Schraml

On September 8th LiSEC has taken over one hundred percent of Schraml Glastechnik GmbH domiciled in Großraming, Austria. Attached you will find the download link to the press release.

The company Schraml is known and recognized for its knowhow in terms of the processing of flat glass and possesses comprehensive expertise in particular in the field of drilling and milling. Othmar Sailer, CEO of the LiSEC Group, about the strategy of the acquisition: “Thanks to the integration of the Schraml Glastechnik GmbH into the LiSEC Group, we are massively gaining knowhow in terms of processing. This will spur the recently established business unit “Glass Processing“. Horst Schraml will not only remain the general manager of this company, he will also be head of the business unit glass processing.”

Flat glass newsletter. Summer 2016

Glasstec 2016

Glasstec 2016 will trakes place in Dusseldorf from 20 to 23 September 2016. It is the most important show for flat glass market, with more than 1200 exhibitors coming from more than 50 different countries.

To come to Glasstec is the opportunity to be informed about the last manufacturing technologies, the flat glass processing, tolls and machines, the last technologies for solar glass, architectural glass, measurement and control technologies.

More over a lot of technical conferences are organized

Lardet mirrors. Chassieu (Lyon)

Michel Morin today thinks of the mirrors of tomorrow

The mirrors still has a bright future. Michel Morin effort to ensure the health of its business in a changing business.

Michel Morin, you control the mirrors Lardet, closely related to the mirrors Favetto.

The mirrors Lardet was created in 1974 and I bought in 2003. I work in conjunction with mirrors Favettto and both companies have historical ties. Moreover, we have combined forces to purchase a building of 1 250 m 2 before investing in new machinery and share our skills to remain competitive in an era that sees, in turn, the Miroiteries disappear . We are in contact with other mirror makers in the region and exchanges allow us to reflect on the evolution of our business and to better negotiate with suppliers.

Explain the work of a glazier.

The tasks are very diverse. In addition, glass processing techniques have changed dramatically in recent decades. The glazier has the skills to shape a glass or a mirror, to the same a damaged part, although this complex task requires hours of work. It's sort of the glass artist in all its forms.

Today, we find the glass in new applications ...

As we were convinced, glass has experienced strong growth in applications for the interior, such as stairs, floor tiles, shower screens or kitchen splashbacks.

What ambition for the future?

The aim would be to work together to better meet the demands and heavy fund buying equipment investments.

A method for hardening glass surfaces award in Geneva

No more broken smartphone screens or scratched watch glasses. The 44th Exhibition of Inventions of Geneva awarded its Grand Prize to an exhibitor from Hong Kong Baptist University for a new curing process glass surfaces.

(Ats) The method involves applying high temperature sapphire film, one of the toughest materials in the world of glass or quartz, said Friday night the show organizers. This very thin layer is sufficient to ensure protection almost equal to that of a block of iron ore.

Transparency is not impaired. The optical transmission of the film is indeed very close to that of glass, between 89 and 92%. The method should interest many areas. It could be applied to all surfaces in flat or curved glass.

Professor Cheah Kok Wai, who won this year's Grand Prix, the rest working in the company Cathay Photonics, a company active in the optics.

The International Exhibition was also rewarded 45 other inventions among the thousands of new products presented.

The Miroiterie Landaise avoids liquidation, continuation plan approved

A long series that ends positively.

The Commercial Court of Mont de Marsan has validated Friday, March 25 the continuation plan presented by the patron of the Landes Mirrors.

A dozen mainly Landes investors commit to provide € 400,000 of new money to revive the company. The 117 employees are relieved.

117 employees of the Landes Mirrors retain their workstation.

Fenzi invests in digital processing machines

The Fenzi Partecipazioni holding company has decided to invest in digital glass processing technologies by buying into the capital of Tecglass, the Spanish producer of very high-tech digital glass printing machinery and components. This strengthens the working partnership of the two leading companies, which have already been working together for some time, and demonstrates the interest of Fenzi in innovations applied to glass while significantly increasing the growth potential of Tecglass on the international marketplace.

Established in 2002 by a group of experts who had a good deal of experience and know-how in this industrial sector, Tecglass has recently studied, developed and produced a range of digital printing machinery specifically for the glass industry. The technology takes the place of traditional decorating methods and offers a simple, efficient tool for applying graphic motifs and photographs directly on glass: ceramic inks can be used on glass for indoor or outdoor use, on sheets of any size (from a minimum of 380×380 mm. to a maximum of 3,300×18,000 mm), with a solution for any type of sector and application.

The sophisticated Tecglass technology fits in perfectly with Fenzi’s strategic vision and natural propensity for innovation which, a company whose financial strength, managerial skills and international sales network, can make the most of the considerable opportunities offered by what is a currently very promising market.

Companies and experts having an interest in this particular glass processing method will now have a new mix of services and products that meet the needs of designers, architects and developers both in terms of aesthetic results and manufacturing capability: Tecglass digital technology is now closer to glass processing companies worldwide and can count on the professionalism and solidity that have set the Fenzi Group apart for more than 75 years.

Reboot float Salaise sur Sanne. France

After 110 days of work, the furnace of the plant Eurofloat Salaise-sur-Sanne (Isère) was inaugurated today by Saint-Gobain Flat Glass and Riou.

€ 26 million were invested for its complete renovation and modernization of the float line which manufactures flat glass for residential and commercial buildings. Prepared for almost two years, this operation was carried out in record time between stopping the output end of January and the first glass poured on 20 May.

Emmanuel ABT, CEO of Eurofloat

This renovation allows to significantly improve technical and environmental performance of the float line with productivity increases of about 10%, from 580 to 650 tons of glass produced per day.

His new oven benefits from advanced technologies to reduce energy consumption by nearly 25% over the old facility and, therefore, CO2 emissions in the atmosphere.

Restarting the float line ensures the sustainability of the French industrial site, the life of the new furnace is 20 years. It is also a guarantee for all local and regional subcontractors, mostly SMEs, working for Eurofloat.

From left to right: Nicolas Riou, CEO of Glass Riou, Pierre Riou, president and founder of Riou Glass Group, Patrick Dupin, director pole Glazing Saint-Gobain and Jerome Lionet, director of Glass Industry.

Joint production company equally owned by Saint-Gobain and Riou Flat Glass subsidiary of Riou Glass Group, Eurofloat produces 22 million square meters of flat glass per year on its float line, 10 million of which are then transformed into glass thin film on the magnetron line and 6 million in laminated glass on its assembly line. Production of the plant supplies the French market and the Benelux.

"This major investment confirms the support that Saint-Gobain wants to bring to the glazing and building market in France. We managed to build with our employees and local communities,modern production facilities, and sober economic energy, consistent with our strategy of sustainable housing, "says Patrick Dupin, director of Saint-Gobain glass pole.

"I am very pleased today to inaugurate this new oven and stand as such to warmly thank the entire team of Eurofloat and subcontractors who worked for his production launched as quickly. Eurofloat is a very French tech industry. A flagship demonstrates the European and world market our know-how of glass products with high added values. Modernizing Eurofloat we invest for the future and the preservation of our jobs in the region, "says Pierre Riou, president and founder of Riou

Flat glass newsletter. May 2016

To contact us: This e-mail address is being protected from spambots. You need JavaScript enabled to view it

Glass Performance Days – 25 Years Anniversary Conference June 28-30, 2017

Dedicated to Information Sharing

The age of digitalization makes customer relationships personal

The Glass Performance Days started in 1992 triggered by the observation that glass processors had something very important in common: Effective use of state-of-the-art equipment and technology. It was equally evident that this know-how was something that needed and could well be shared. The road from a seminar with limited participation to a truly global, world-leading conference was swift and successful. The dynamo of the concept and long-time Chairman of the Conference Organizing Committee Jorma Vitkala sets the essence and substance of the Conference into perspective:

- The success formula we have followed is crystal clear. We have always believed in the power of information sharing for the development of the industry. In fact we have worked from the hypothesis that information is the only commodity that grows from continuous sharing, he says. When information sharing is conducted in the manner that we call the GPD Spirit it produces results. We have seen that this atmosphere creates benefits for all and the more experience participants possess the better information sharing travels between them. The search for new forms of cooperation and information at the GPD is on-going. In this way participants and speakers have made the Conference into what it is and the organizers are naturally more than grateful in being able to facilitate this high-level exchange.

A note of appreciation

The GPD has worked from a platform of cooperation since the beginning. The participants and sponsors as well as the organizations behind them have contributed remarkably to the common good.

- There have been many spinoffs from the GPD, regional conferences have followed and the formula has been generally accepted and even served as a catalyst for other events, Jorma Vitkala says. Our supporters and contributors deserve genuine appreciation for the input they have contributed and that has made the Glass Performance Days into what the Conference is today – not to mention what it will be tomorrow.

25 Year Anniversary next

Now that the Glass Performance Conference heads towards its 25 Year Anniversary in what will be the 16th Conference June 28-30, 2017 GPD can look back at an impressive record of collecting and sharing glass industry essentials. A total of over 13,000 delegates have attended 3,000 presentations, listened to 1,000 speakers and formed 30,000 contacts over the years.

But a Conference like the GPD is much more than impressive numbers. It is a get-together that brings specialists together for the purpose of learning from an open exchange of information on a personal level. Above all it is something that changes very much over time as experiences and business environments develop. One of the main reasons for going to the GPD is to sense the atmosphere of the times together with colleagues. Business development has a lot to do with intuition and creativity. To stay competitive professionals have to stay in the mainstream of the leading trends. Development is driven by people and that is very personal. The same applies to the career paths of glass professionals. New experts enter the scene, others may leave it but the core remains to pursue continuous development.

- As important as the live Conferences are networking and continuous development is in no way limited to the physical conferences only, Vitkala observes. Web documentation and professional portals are open for facts presentations within the world of glass between conferences as well. The Glassfiles-portal that started up earlier now contains some 8,000 pages of technical articles and offers GPD-speakers an opportunity to communicate with the registered users of the portal.

Bloggers welcome

The latest addition brought on by the digital age is the www.glastory.net portal introduced and spearheaded by Miika Appelqvist of Glaston.

- We have taken on this initiative to serve the entire supply chain of the glass business, from designers to researchers and industry. The mission of the portal is to invite and serve individual bloggers primarily from our GPD sponsor networks representing professional views on the development of the glass business to share information with colleagues on-line and to form acquaintances that go beyond sheer business relationships. The professional respect gained makes on-line contact activity quite personal, Miika Appelqvist remarks.

The next generation

- Twenty-five years could well be labeled one generation in the life of a business, Vitkala ponders. Many things have changed and some essential basics, like the physical properties of the glass material, have remained the same. New technology has been adapted to the inherent physical properties of glass and new products have been developed by utilizing the best the material can offer. A look at today´s city planning and building designs plus the requirements put on energy-efficiency, environmental comfort and stylishness reveals how far we have come from the very first use of glass to cover window openings in buildings, Vitkala reflects. Looking back at the major advances of the latest 25 years of the glass industry one has to mention coating technology, especially LowE and solar applications that have hoisted energy-efficiency to a completely new level. The changes and shapes of modern building design, increased glass sizes, new bonding techniques and the use of glass as a structural element are other notable and significant advances.

Essential GPD features

The special workshops arranged in conjunction with the GPD are tailored for special audiences that have the need for hands-on information on specific issues. At GPD 2015 one of these was the spotlight put on high-rise construction. The lecturers represented leading experts on high-rise and participants were particularly appreciative of the special challenges attached to high-rise – quite different from normal housing or low-rise construction. This workshop proved to be a real eye-opener even for experienced and widely recognized architects. Quote:

- The significance of extensive experience was very evident, special buildings have special demands and the technical requirements of high-rise increase exponentially. The presentations by Keith Boswell and Leon Jacob complimented one another extremely well, from the inside out (building typology and space allocation) and the exterior (curtain walls). The GPD is a super concept, in one-two days one can amass a lot of information, the internet-summaries are excellent, too (Pekka Helin, Pekka Helin & Co. Architects).

Although the GPD is an international forum and English the language participants represent different regions of origin. Some participants hosting business partners at the Conference have arranged simultaneous translation to make sure nothing is lost behind any language barrier. These visitors voiced both appreciation and thankfulness for this special consideration.

The effort of the organizers to screen and streamline presentations added a lot to their clarity and visual appearance. This clearly contributed to the efficiency of communications and also helped keep presentations structurally uniform and within their allocated time frames.

The 16th GPD in its 25th year also coincides with the 100th Anniversary of independent Finland – the home of the main Conference since its beginning. That fact will also contribute to the feeling around the Conference that takes place at the height of the Midsummer season in Scandinavia.

The Aniche float will restart

In mid-September, the float Aniche restart. After an eternity. In April 2012, the furnace went out. After being trained in the new process, workers will produce new glass. But with a small change. Dedicated far the only building market, the site will now produce predominantly for the automobile.

After sixteen years of operation in April 2012, the glass furnace of Saint-Gobain Glass France was dying. But it was better for résuciter. By a company agreement signed in March 2011 by all unions, management pledged to invest 26.6 million for the modernization of the site Aniche. Bodes well for the plant, a thirty-five float glass production units of the Saint-Gobain Group worldwide. Except that the restart was much, much longer than initially announced. Of deferrals, the oven 350 meters long, will have remained more than four years off!

"We were expecting this news with impatience. Staff clung to restart ", recognizes, relieved, Christian Brice, who during all these years has drawn many bells, the Officer of Saint-Gobain France, policies ... What was the daily employees during these four years? Management has posted to some other sites. Of Anichois worked at the Saint-Gobain plant Eurofloat Salaise-sur-Sanne (Isère). It also has been shutdown to be equipped with a new oven. Homecoming of anichois workers who themselves have lost none of their experience (see below). "An oven, it does not call into heated overnight. It takes a month to get the correct glass, "says Christian Brice. The rebuilt furnace has a capacity increased to 670 tons / day against 600 tonnes / day in the former and reduced energy consumption by 15%. And it will not produce as glass for the building. "Its use will be mixed, automobile / construction, with a predominantly auto assignment," says management.

Set foot in the stirrup. For C. Brice is the number 1 concern for those employees who were no longer in contact with an oven. "We must reclaim the manufacturing process, become familiar again with the safety rules ...", means the union. Adding: "Everyone will be holding sleeves. It is not about to slow restart. This restart is excellent news for the labor pool. " In the coming months, staff will undergo a training program. Especially as the management indicated that it plans to hire twenty people. "Before the stop, we were 206. And I am not talking precarious and employees of subcontractors, C. Brice said. Currently we are 180

Dear Spectrum Glass Customers;

We are making an extraordinarily difficult announcement today. After serving the art and specialty glass industry for 40 years, it is with very heavy hearts that we must announce the closure of Spectrum Glass Company. Due to several factors, it is no longer financially feasible for our company to continue to operate.

We will continue manufacturing through June and July 2016, and will sell the product inventory currently on hand over the months ahead.

Please know that our primary concern is to help ease this difficult transition for you and all the people we’ve been proud to work with and serve. We are exploring opportunities to transfer our product lines to other manufacturers to help minimize disruptions in sourcing.

We would like to express our deepest gratitude to all of our partners, customers, artists and others who have supported Spectrum Glass over these past four decades, and who continue to support us now. We will communicate updates here and via other channels as we wind down our operations.

Chartres stained glass exhibition

June 15 to October 15, 2016

Chartres, The Stained Glass Gallery

15 artists are invited by The Stained Glass Gallery

to provide a window on the theme of Chartres

Pierre Carron, Valerie Gaugeac, Tetsuo Harada, Nathalie Lefevre Genevieve de Marcellus, Jean-Luc Parant, Joedane Ribaud Beatrice Roche-Gardies, Isabelle Rosenberg, Alice Sancey, Didier Sancey, Agnieszka Sekita-Lefèvre, Luc Thieulin, Antoine Vincent, Leslie Xuereb.

Coming from different backgrounds, these painters, sculptors, visual artists or writers, living or having Chartres euréliennes ties reflected at the request of Natalie Zins Loire, a work on the theme of Chartres. They then worked with Jacques, Bruno and Hervé Loire, glassmakers in Lèves, to translate their project with the glass material.

The Loire workshop at their disposal their different expertise: colored glass set with enhanced lead or not grisaille glass tiles set with resin, fused glass, thermoformed glasses ... The artists, some of whom had never approached stained glass, chose the technique that best suits their project.

Each with his artistic sensibility, offers his vision of Chartres. The compositions, often figurative, evoke the city through its essential items such as the cathedral, light, scent, but also the Beauce. Others evoke more symbolic or abstract attachment to Chartres.

Explosion of colors or sober colors, variety of styles and expressions, technical prowess, these windows reflect the dynamism of the contemporary art of stained glass.

These works, intended for fans or collectors will take place in homes or public spaces.

It was in 1976 that Micheline Loire opened at the foot of the cathedral of Chartres, The Stained Glass Gallery, which promotes the art of stained glass.

Each was a stained glass exhibition dedicated to young or new talents, a technique or a theme is presented. In 1996, to celebrate the 20th anniversary of the gallery, the exhibition "Chartres Stained Glass" presented stained glass made by master glassmakers and artists on the theme of Chartres.

In this 2016 year for the 40 years of the Gallery, Natalie Zins Loire chose to extend the event by calling on 15 euréliens artists.

FROG: A new system for glass inspection

When industrial innovation deals with glass crashing and quality control

Have you ever thought about how the glasses of your car would break in case of a strong collision? In many pieces of course, but how many? And how big? Indeed, the number and size of the glass fragments are very important as far as security is concerned.

We are talking about tempered glass, the glass undergoing a specific tempering process including heating and subsequent cooling. Such process renders the glass about four times stronger than "ordinary", or annealed glass. Unlike ordinary glass, which can shatter into jagged shards when broken, tempered glass breaks into small, relatively harmless pieces. This is why tempered glass is used in those environments where human safety is an issue. Applications include side and rear windows in vehicles, entrance doors, shower and tub enclosures, microwave ovens and skylights.

To check the size and the number of fragments in a given glass product in order for such product to meet quality control and security criteria: this is the need of specific glass manufacturing processes. And here’s the invention from Deltamax Automazione, a company from Trento with over twenty years experience in industrial automation and machine vision, and whose mission is to guide its customers in using innovative technologies in order to improve effectiveness and efficiency in production processes.

FROG (Fragment Recognizer On Glass), this is the name of the new system, is a rational and user friendly interface for automatic visual inspection of glass products.

But how does it work? Chiara Corridori, Deltamax Technical Manager explains: “FROG can automatically recognize, count, analyze and classify glass fragments following a glass product break. In addition, it can store the images and the results processed to generate customized reports”. She continues: “The main component of the FROG system is the inspection unit, connected to a PC and to the electrical cabinet: the user can move the system to the desired position and select the analysis functionality in the graphic user interface. At the end of the analysis, the system releases a report on the test results, including the image of the glass as acquired by the camera, the number of fragments identified and the size of the biggest fragments”.

“The advantages of an automatic system for counting fragments compared to a manual counting system”, continues Chiara Corridori, “are obvious: quicker and objective results, in accordance with identified standards, and possibility of data storing. Thanks to the use of direct light, FROG is extremely easy to manoeuvre and suitable to be used also with printed glass: two features that make it stand out from competitors using backlight illumination. In addition to the new use, the market appreciates the solution because of the convenient price and because it needs no installation”.

FROG stems from Risolvi, acronym of “RIcerca di SOLuzioni di Visione per applicazioni Industriali” (research of vision solutions for industrial applications), a research project funded by the Trento Province between 2011 and 2015, which has allowed to implement prototypes able to innovate GlassInspector, the system created by Deltamax using camera technology to recognize and catalogue defects, and to inspect glass sheets directly on the production line. The research project has been carried out in collaboration with the TeV group from the Fondazione Bruno Kessler (Fbk) research centre in Trento. The collaboration has been very successful as it involved the transfer of know-how on Image Processing algorithms as well as software System architecture. As a consequence, a scientist from Fbk is now employed by Deltamax.

Furthermore, together with Fbk, a new software architecture has been designed and implemented (DVS – Deltamax Vision System), which provides new applications with flexibility, expandability and ease in configuration.

This allows computer scientists to reduce developing time and the system installers to modify the parameters in order to adjust the system to a new need without modifying the code.

The artificial vision system, i.e. the use of cameras and optical sensors for the acquisition of images and for the automatic search of defects, derives from the so-called Machine Vision, a branch of Systems Engineering requiring different competences and relying on mechanical-optical-electronic-software systems integrated solution for examining natural objects and materials, human and industrial artifacts and manufacturing processes, in order to detect defects and improve quality, thus increasing efficiency and safety of both products and processes.

Recently, Deltamax invented an innovative solution for improving systems for defects identification and classification. For such systems, both the hardware (illuminator and electronic control cards) and algorithms have been developed. For example, starting from an algorithm conceived by researchers at the University of Munich for highlighting streets in satellite images, Deltamax has implemented a new algorithm able to identify scratches in flat glass surfaces images as if they were streets. Scratches and streets in fact share the same geometric characteristics: length, thinness, and curvilinearity.

Gianluca Diener, manager of Deltamax Inspection Technology area, concludes: “The impact our research has generated is tangible: over the last four years in the artificial vision area the 3 initial people that work on software development have now become 7, of whom one is the researcher collaborating to the Risolvi project. Moreover, the feedback from the market is positive and we already face an increase in our sales”.

Change in the distribution of machinery for flat glass in France.

A change in the shareholding of Pacard distributor has had consequences for some redistribution of commercial cards.

The arrival of Eric Laurenty in Pacard facilitated the entry of CMS in Pacard instead Intermac. CMS had no real distribution structure for its business machines for glass since the departure of Patrick Guévard and was able in this way to rebuild a place on the French market.

To contact us This e-mail address is being protected from spambots. You need JavaScript enabled to view it

News for flat glass processing markets. April 2016.

Discovery of the oldest glass furnaces Israel near Mount Carmel

glassmaking furnaces dating back to the late Roman era were discovered at the foot of Mount Carmel, between junctions Ha-Amakim and Yagur, announced Monday the Israeli Antiquities Authority (IAA). This archaeological discovery is further evidence of the place occupied by the Israeli glass industry on the international stage.

Israel, a major glass production center

Furnaces glass splinters, discovered during excavations carried out in the framework of a railway project underway in the Jezreel Valley, prove that Israel was indeed a leading glass production centers of the ancient world .

"This is a very important discovery with implications for the history of the glass industry both in Israel and in the entire ancient world," says Yael Gorin-Rosen, chief curator of the department glassware in the AIA. He added: "We know from historical sources dating back to the Roman era that the Acre Valley was famous for the excellent quality of its sand, particularly suitable for the manufacture of glass. Chemical analyzes of glass utensils from this period discovered in European sites and wrecks of sunken ships in the Mediterranean region have proved that the glass is rooted in our region. Now, furnaces have been discovered, for the first time, where the raw material used to manufacture the glassware was produced. "

The extraordinary results of these almost accidental excavations have attracted glass experts worldwide. "This sensational discovery is of great interest for the understanding of all the glass trade system in antiquity. Here we have evidence that Israel was a production center of international importance; his drink was widely distributed in Europe and all the Mediterranean countries, "says Professor Ian Freestone of the University College London, an expert in the identification of the chemical composition of the glass.

The site was located by Abdel Salam Al-Sa'id, an inspector of AIA who oversaw the construction of the new railway line linking Haifa to the east. The archaeologist, whose task is to ensure that the work does not affect sites that may have historical significance, discovered pieces of raw glass, antique stalls and a layer of ash in a trench. "We also found pieces of glazed bricks from the walls and ceiling of the oven," says the director of excavations.

Industrial production for a growing market

Furnaces included two compartments: a combustion chamber where burning kindling to obtain a very high temperature, and a melting chamber in which the raw materials (the pure sand and salt) were inserted and then fused to a temperature of about 1200 Co. The glass was then heated for one to two weeks, until huge pieces of raw glass are formed. Some weighed over 10 tons. At the end of the production process, the ovens were cooled and the glass pieces were broken into smaller pieces and sold to workshops where they were re-melted to produce glassware.

The use of glass has largely developed in early Roman times, because of its characteristics very popular: its transparency, beauty, delicacy and manufactured utensils and speed production blow. Become a necessity in every home of the Roman Empire, glass was produced in industrial quantities in specialized centers. The site discovered in the Zvoulon Valley is an excellent example of such glass manufacturing centers.

Remember also that the edict of Maximum, issued 301 of the vulgar era by the Roman emperor Diocletian, mentions two types of glass: the first known under the name Judea glass (that is to say, the Land of Israel) and the second glass of Alexandria (Egypt). The glass Judea was light green and cheaper than Egyptian glass. This discovery now allows to locate one of the centers where this had occurred prized commodity in the Roman Empire.

The ovens will be transferred to the regional school "Carmel Zvoulon" and exposed to the public in a few months.

Mr Mercier At Bottero France

He joined the Bottero Group to handle the marketing of the range machinery for flat glass on the western half of France. Mr. Mercier is well known in France on the market of mirrors where he held several technical manager.

New job for Mr Piscina in France

The former leader of the mirrors Technidécors left Bottero he joined there more than a year as a sales engineer to join the mirrors Parmentier. Then left Parmentier some week ago to join Intermac.

New web site for Bavelloni

Bavelloni SpA announces the launch of their new web site. Bavelloni.com, the new Bavelloni SpA web site is now online. Easy-to-navigate, accessible on PC, tablet and smartphone, the site intends to mirror the Company, where tradition and experience evolve in a dynamic and modern context. By this new web platform, now available in Italian and English, Bavelloni SpA will be closer to their customers: this project represents a milestone for relaunching the brand globally. Design and innovation have always been Bavelloni’s goals and the site is perfectly in line with that. The products are in the foreground: strong impact images and contents showing Bavelloni technological solutions in a clear and immediate way. The site also includes a session focused on the Company’s long history, an overview of after-sales services and some galleries with case histories, events and the wide Bavelloni SpA sales partners’ network all over the world in a glance.

Riou glass invests in Canada

Nicolas Riou, director general of the French family group Riou Glass, a leading player on the French market of the window, takes a stake in the ThermoVer flat glass processing company, located in Saint-Léonard, near Montreal.

This young Canadian 80 employees company, founded in 2015, transforms glass products to professionals of the carpentry, the facade and the interior.

This is not directly Riou Glass that performs this external growth operation but a new entity called "Riou Glass" which Nicolas Riou is the main shareholder and the Riou group, a minority shareholder. The contractor, son of the founder of Glass Riou Pierre Riou, becomes co-chair of the Canadian Thermover.

Thermover serve as an entry point Riou Glass for the manufacture and distribution of its latest technological innovations in Canada. Including Calorglass launched by industrialist in 2015, transforming the glass walls in an electric heating system by radiation.

AGC Glass Europe to refurbish its Cuneo float plant (Italy) in 2017

AGC Glass Europe has planned to carry out the refurbishment of its Cuneo float glass line in Cuneo (Piemont, Italy). This investment of around 25 million euros is decided not only by the positive impact that it will have on the productivity of the plant and the expected environmental benefits, but also by the prospect of extending its current range of products.

The refurbishment including design improvements will significantly boost the plant’s capacity and reduce its energy consumption, with a corresponding positive impact on its yield and product quality. The reduced energy consumption will also mean a large reduction in atmospheric emissions, with 50% less CO (carbon monoxide), 14% less CO2 (carbon dioxide) and 30% less NOx (nitrogen oxides). This improved environmental performance in turn will make the plant eligible for the energy certification system operated by the Italian government, with subsidies granted over a period of five years in proportion to the energy savings achieved.

Together with the future gains expected from the cogeneration project, these developments will significantly boost the competitiveness of the Cuneo plant.

Receivership Peinture Miroiterie Sols, France.

Painting Miroiterie Sols acting as the Pms located in Bagnolet (Seine-Saint-Denis) was declared in receivership by the court of Bobigny Court Of Commerce. The RCS number of this case is 317,693,067.

Tempered glass for diving mask.

Specializing in optics for the sport for 65 years, Demetz launching a new range of diving mask adapted to both scuba diving at snorkeling.

The model, called X-Vision Ultra Liquidskin, brings comfort and ergonomics with its adjustable buckles quick fastener attached to an ultra flexible skirt. Side materials, the silicone was used for the skirt and strap while the mask in "tri-comfort", a flexible material, provides maximum comfort during frequent or long dives. With a wide field of view and a small volume of air inside, this product allows to explore and enjoy the seabed in the best conditions.

The mask is equipped with glass lenses soaked in order to improve its mechanical properties. Its resistance is two to five times higher than traditional glass and ensures more security in case of breakage.

Various possibilities lenses are proposed: colorless glasses, black glasses, silvered or gilded mirrors.

Glass. Transparency and reflection

Where would our civilization without glass? What would we be if man had not invented this material and its applications, windows, mirrors, containers, lentils .... ? What is the importance of glass in our progress?

The glass appears to be an essential material of our civilization, especially if one adds his contributions in the field of art (stained glass, mosaic ....).

Serge Bramby analysis in this book, civilization by civilization that brought this material as the technical side as artistic or scientific.

Serge Bramly

Transparency and reflection

JC Lattes

Vie et verandas is growing

Vie and verandas which ended 2015 with a turnover of 30 million Euros representing 3% of the French market's objective is to reach 50 million euros in 2020 increasing by 50% its number of commercial agencies .

Lyonnaise 250 employees (based in Feyzin) is still controlled by the family Pinoncély which bought the company in 1996. The Verandas (half aluminum half wood) are all manufactured in the Feyzin where they go to shop glass already integrated for mounting on the customers site.

The company recently invested in its range Verandas wood in a sanding machine and a new cutting line for aluminum range.

Flat glass newsletter March 2016

To contact us : This e-mail address is being protected from spambots. You need JavaScript enabled to view it

Very strong growth in Internet sales of wheels for mirrors machines.

Vedip, the first European site (French origin) Internet sales of Italian wheels for mirrors machines saw its revenues for the first quarter 2016 increased more than 3.

Orders booked in the first three months represent over 75% of total sales in 2015.

The strategy developed by Vedip to propose, in partnership with a leading Italian manufacturers of wheels for mirrors, very competitive prices for working only on the Internet, detailed fact sheets with photos, standard wheels made by manufacturers / Machines / Positions, alternative wheels and a telephone support seems to meet the needs of the market in Europe mirrors.

The site already has 861 tools now online continue to improve the technical data of the tools and the number of referenced machinery (over a hundred).

On Vedip you can view the data sheets (with photos and price) of the wheels for the main flat glass processing machines of the market (straight line edging machines, CNC, drills, double edger, chamfering ...) and the most important suppliers (Intermac, Bovone, Glaston, Bavelloni, Lattuada, Schiatti, JANBAC Baudin, Battelino, Denver, Bimatech, Ada, Besana, Bottero ....).

Contact : This e-mail address is being protected from spambots. You need JavaScript enabled to view it

Tel ![]() 00 33 782 39 43 3400 33 782 39 43 34

00 33 782 39 43 3400 33 782 39 43 34 ![]() 00 33 782 39 43 34 00 33 782 39 43 34

00 33 782 39 43 34 00 33 782 39 43 34

LiSEC Cutting Table used in the Tyrolean Glasfachschule (School of Glassmaking)

Since September 2015, the HTL (Polytechnic Glass) Kramsach in Tirol is using a LiSEC cutting table „base CUT“ for the education of the students.

Analogous to industrial enterprises it is also particularly important for schools to get quality by means of modern and state-of-the-art machinery. After more than 20 years of use, the HTL Kramsach replaced the previous manually operated cutting table by a LiSEC „base CUT“. After having compared different manufacturers in the market, the HTL quickly opted for the Austrian machine manufacturer. Originally known as an industrial brand for the high-end sector (regarding quantity, quality and price), LiSEC with its base series now provides relatively affordable machinery for newcomers in the industry, small-scale enterprises or the use in schools. For the headmaster, Dr. Ursula Pittl-Thapa, a former graduate of the polytechnic herself, the LiSEC cutting table was „Love at first sight“.

Established in 1948, the educational institution comprises a polytechnic for glass, the faculties glass and technology, glass and design as well as, for three years now, a HTL chemistry. The graduates of the HTL Kramsach, 361 students are educated at present, are very sought after in the glass industry and they cover a comprehensive spectrum of jobs, from the specialist for restoration up to the consultant in statics and façade engineering. „The base beginner’s model is ideal for polytechnics and/or vocational schools in terms of price/performance and it provides “LiSEC quality at an affordable price”, says the native of Innsbruck who herself has processed glass for a while and who has “dragged around quite some glass sheets”. Due to the education purposes and the operation by inexperienced persons, the high degree of service of LiSEC constituted a critical purchase criterion when it came to the decision.

Klaus Preyler, LiSEC Sales Director, who handled the sale: „During their education, the students in Kramsach are now learning how to handle the best machines in the market– best in glass processing, from the outset!“

Auction on Thursday 28 April 2016

For the modern and well-maintained glaziers with insulating glass production and equipment and the plant and business equipment of the company:

Flachglas Buxtehude GmbH

Weidegrund 9a

21614 Buxtehude / Germany

Turn in Sorèze Glass Museum. Madeleine Bertrand succeeds Geneviève Blaquière.

Founded in December 1997 by Yves Blaquière the Sorèze Friends Association was to manage the Glass Museum and to focus on the cultural life Sorézienne in general.

Madeleine Bertrand explained at the meeting that the association would now devote himself to the glass by organizing temporary exhibitions, collections zoom and rotate to present to the public. It is in this light work around the glass the assembly valida the proposed new name of the association which is now called The Glass Museum in Sorèze (MVS).

Madeleine Geneviève Bertrand thanked Blaquière for its commitment and action for the association since 2010, where she will continue to work within the team as Vice President. Geneviève Blaquière headed the museum for many years succeeding her husband Yves (initiator of sorézien Glass Museum).

Now, a new page opens for The Glass Museum in Sorèze!

Note that currently work in the Sorèze Glass Museum is expected to open in mid-April. This e-mail address is being protected from spambots. You need JavaScript enabled to view it .

New headquarters for Guardian

The new European headquarters of the company leader in the manufacture of finished products in glass was inaugurated Wednesday.

Last summer, Guardian Industries, the leading company in the manufacture of finished glass products, has established its European headquarters in the industrial zone of Bourmicht in Bertrange. Wednesday, the building of 2100 m² was inaugurated in presence of some officials and the Minister of Economy, Stephen Schneider.

According Guus Boekhoudt, Vice President Europe, 120 people work in the building. It includes, among others, marketing, finance, legal and taxation. In all, the company employs in the Grand Duchy between 700 and 720 people, divided between headquarters and factories and Bascharage Dudelange.

"It is important to separate the seat factories," said Guus Boekhoudt. The finished glass products for the automotive (eg windscreen) represent "less than 10% of our business," said Vice President Europe. "The majority of business relates to the residential and commercial premises," he said.

A glass slide in the sky

A glass ramp will take place over the void, at 304 meters, against a building in Los Angeles. Breathtaking!

To take the air, the occupants of the US Bank Tower in Los Angeles, California, will only have to drag from one room to a terrace, a glass ramp, perched above the void, to 304 meters.

An unusual attraction called "Skyslide" that give the illusion passengers to slip into the air. The 11-meter-long glass slide will move from stage 70 to 69th, while enjoying a nice view, provided you do not get dizzy. But rest assured, the closed passage is composed of solid walls 10 centimeters thick.

The attraction is scheduled to open in a few months. To access the huge terrace, you will take out a ticket at $ 25 price and count a surplus of $ 8 to slide down the slide.

Official dates for Vitrum 2017

Glass industry next Italian show will be in Milan on 3-6 October 2017 for the 20th Vitrum

Small technical manual. Use and choice of wheels for mirrors machines.

The online sales site Vedip of Italian wheels for mirrors machines has posted a technical manual that contains a set of technical points to select and use the best diamond wheels and polishing all mirrors machines.

Recent Articles

-The Diamond drills

-The Segmented wheels

-Settings wheels working on CNC machines

-The bonds

-Data on technical cooling

-The diamond

PROPERTIES OF CHEMICALLLY TEMPERED GLASS

Physical properties

Type of glass

- Sodium-calcic glass

- Glass materials with special chemical composition.

Thickness of glass

- From 0,5mm

Maximum size of glass

- 3200x2200mm

Mechanical properties

Deeper of penetration

- 20-100 micron

Bending resistance

M.O.R.ASTM C 158-95.

- 300-600Mpa

Different values, harder then the above ones, can be obtained depending on cycle length and temperature.

Value must be selected according to special project requirements and articles use conditions.

Working

- Chemical tempered glass can be successively cut, ground, drilled, shaped and decorated.

Acquisition successfully concluded

HELANTEC under new management

The two managers, Jochen Weiß and Gregor Witrofsky, who for more than 10 years have been a fixed component in the company and who have played a key role in the continuous development of the company, have jointly taken over the management of the company. Over the last 10 years new technologies have been introduced, the product spectrum has virtually been doubled and the internal quality assurance has been optimised.

The corporate structure remains intact, product development will be driven forward and direct customer support will be intensified. Initially the focus will be expanding the insulated glass business segment. Systems for monitoring various production processes for the manufacturing of insulated glass are almost ready for market introduction and additional products are in development.

"Manufacturers of insulated glass have a competitive advantage through the use of HELANTEC products; and in everyday operations they more easily meet the constantly increasing market requirements", explains Gregor Witrofsky (36).

"Custom webinars, online presentations and personal customer visits are planned for intensification of customer support. Due to the global export business and to ensure the best possible support, the network of our sales partners will be further expanded", adds Jochen Weiß (38).

The worldwide demand for insulated glass represents significant potential for HELANTEC GmbH. Thanks to experienced developers and a reliable production team the new managing directors look to the future with confidence.

New start for AGC Moustier

AGC Glass in Moustier is going up a production line, but not a new one. These are the machines Site Athus in southern Luxembourg that is transferred to the Basse-Sambre. It was announced a year ago. On one side we stop production, the other one goes back and construct a new tool. Athus was losing money Moustier away from where the glass he used was produced. Tomorrow everything will be manufactured in the Basse-Sambre.

The aim, improve profitability

There will be transportation to carry the flat glass produced in Moustier to Athus where it was processed into laminated glass for the construction market. Then he returned to Moustier for packaging and shipment to the customer. It is a significant saving. With this concentration of means of production on one site AGC tries to resist the crisis that has hit the flat glass sector since 2008. With the result, excess capacity and the closure of production units across Europe. We remember that in Belgium the neighboring sites of Saint-Gobain Sekurit Glass and put the key under the door there two years ago. We also remember that AGC had arrested a closed oven Moustier no in 2012. AGC Glass Europe has also closed a plant in northern France and another in the Netherlands. Today, the group feels happy to have arrived at a better balance between supply and demand. But he dare not bet on the future.

Fewer job creation at Moustier

With the transfer of south Luxembourg activities to the Lower Sambre, 85 Athus operators will lose their jobs. But Moustier, only a small half, about 40 position will be created. Athus workers are obviously a priority. But they live near the Luxembourg border, at least 160 km. There are therefore three executives who have accepted the proposal. Two former employees of Saint-Gobain Auvelais were also hired.

The new laminated glass line should be ready in late June.

Statistical Portrait of the branch of mirrors: a majority of TPE and stable jobs

AGEFOS SMEs publishes the results of the statistical portrait of the branch of the mirrors. It includes all companies with activities such as the marketing and implementation of flat glass in the building and decoration.

Panorama companies

The branch has two main business areas: painting and glazing for 25% of businesses and shaping and processing of flat glass for 44% of them. It gathers 64% of employees.

The geographical distribution of companies is close to any sector since they are mainly located in the Ile-de-France (17%), the PACA (13%) and Rhône-Alpes (10%). In contrast, only 11% of employees work in the Ile-de-France, against 24% for the whole economy.

Finally, 15% of employees working in the branch of TPE, against 29% for the whole economy.

Stable jobs

Men represent the majority of employees, 76% against 53% in any sector; this can be explained by the industrial character of the area. Furthermore, 22% of employees are under 30 years and about 10% are between 55 and 60 and over, the distribution by age is similar for men and women. The branch has 59% of workers, among whom 70% are men. As for women, 54% of them are employed. Finally, the employment contracts of CDI rate reaches 90%, or 30 points higher than that for the overall economy.

Presentation of the activities of the branch

Professional branch of mirrors, glass processing and trading groups all enterprises whose main activity is the application of glass techniques for the marketing and implementation of flat glass: window, facade, interior design , equipment, furniture and decoration. The branch consists of two main sectors: glass processing and installation of windows, and four professional categories: glass processing, trade, construction and the installation and logistics.

Methodology of statistical portrait

The statistical portrait of the branch is to describe the characteristics of companies and employees. The methodology is based on processing the latest data from the DADS made available by INSEE. Performed at an annual rate, this study also observed on trends in employment and tr

Flat glass and glaziers newsletter. February 2016.

To contact us : This e-mail address is being protected from spambots. You need JavaScript enabled to view it

Glass middle East 2016

Glassman exhibition and conference

10th 11th May 2016

Abu Dhabi UAE

GPD China

In 2016, GPD China will be held on the 9th of April in Shanghai, just before China Glass exhibition. The event will focus on the current trends in the following areas;

- glass production and processing

- use of glass in buildings, transportation and energy management

Over 300 industry experts are expected to attend.

New deadline for the resumption of miroiterie Landaise

The Commercial Court of Mont-de-Marsan could not make a decision Thursday 11-02, about the future of the Landes Mirrors. The recovery plan presented by its Chairman, Serge Delwasse, and his associates could not be validated because the court wants more accounting information to make its decision.

He fixed as the date March 4 to produce these pieces, reserving deliberated for Friday, March 11. However, the situation should evolve favorably, because the buyers offer a recapitalization of € 1.5 million, including 800 000 in cash, and want to keep the remaining 117 jobs.

Loïc Barscaq, managing employees, wants to "remain optimistic, keeping the confidence of customers and suppliers. But for this, it will quickly go out of the period of receivership. "

Open Days Intermac

Pesaro, Italy 17 to 19 March 2016

Intermac invites guests to Pesaro, Italy, in the heart of productive establishments Intermac, world leader in the processing of glass, stone and metal. computer demonstrations, and new machining solutions designed to increase productivity and quality, specific seminars and demonstrations in real time!

Glass

• Work on small glasses with the Master machining center.

• Automatic repositioning of the cup during implementation and blocking falls on Vertmax vertical center.

• Removal of weakly emissive layer (LOW-E) on a cutting table Genius (float).

• Integrated printer on Genius (float).

• Cutting diagonalesautomatiques on laminated glass.

• New on the waterjet cutting center PRIMUS 3 and 5 axes

New unit for K Line, aluminium joinery.

Friday, February 12, 2016, André Liebot, the company president symbolically laid the first stone of the future plant that K • Line will operate by 2018 in the Plaine de l'Ain, huge industrial area located about thirty kilometers from Lyon. Back on the occasion of this ceremony, on this major industrial project in the aluminum joinery sector in France and about which we begin to better know the details.

Next 2016 glass fair

China Glass 2016

Shangai annual glass exhibition

From 7TH to 11th 2016.

Shangai China

Label Product BTP. Two glass product

With a rating of 4.6 / 5, the specialist turnkey photovoltaic solutions for roofs SOLARWATT has received the label "Product BTP 2016" and shows "confirm its place among professionals and demonstrate its ability to offer innovative solutions in line with the market. "

Elected in the "technical equipment", the photovoltaic panel SOLARWATT biverre Style 60P combines "maneuverability, efficiency and robustness."

For the company, this label underscores the headlights advantages of the product for all solar rooftop installations of any size and kind, including its unmatched guarantees: "Better, he paid tribute to the work of the Solarwatt R & D teams from 1998, year of release of the first bi-glass business unit. "

"We are honored and proud to receive this distinction It welcomes a product that fully refl ects the mission that we fixed. Make every solar roof project a success, in terms of performance and durability" welcomed Eric Gautier, Sales Engineer Key accounts at SOLARWATT France.

A distinction recognized by construction professionals

Initiated by Sageret, this annual list, praised and recognized by construction professionals,, it identifies and rewards the most outstanding products.

SOLARWATT France has therefore here unmarked in front of more than 250 000 companies in the construction and 30,000 prescribers who gave their avissur a selection of innovative products and speaking out on 4 criteria: innovation, design and usability, relevance and usefulness for purchase.

SAUDI ARABIA Exhibition – A GLOBAL BUSINESS POWER FOR THE GLASS , ALUMINUM AND FENESTRATION INDUSTRY.

May 1 -4, 2016 at Riyadh International Exhibition Centre will be staged again Glass & Aluminum Saudi Arabia Exhibition with more than 110 exhibitors from the Saudi key players and global manufacturers, technology suppliers and distributors; taking part in the region’s exclusive and complete event for glass, aluminum and fenestration industry.

The Saudi construction sector looks set to expand by 7.8% between 2015 and 2019.The sector's sustained growth - supported by government policies, an expanding population and economic prosperity. With more than $732bn, the Kingdom Saudi Arabia currently boasts by far the largest construction sector in the MENA region and one of the most rapidly growing globally. These expansions leads to the growth of the window and door market substantially as well as the flat glass usage

Glass & Aluminum Saudi Arabia 2016 will take place alongside with WinDoorEx Saudi Arabia Exhibition, the international exhibition for doors, windows and facades, provides exhibitors with a powerful marketing platform that will position your brand among the regional industry leaders and global suppliers and create an even better visitor.

Riou will repackage its float glass in France

The company saw Riou Glass historic hours. After 15 years of service, the oven of Eurofloat plant near Lyon needs uen major maintenance.

"THE ONLY INDEPENDENT LAUNCH FOUR"

Specializing in glass processing, the company installed near Pont-Audemer has engaged in a risky venture: producing its own glass to be completely autonomous. In 2008, the glass shortage pushes the founding president Pierre Riou to secure supplies. The group employs around 1,000 employees in six locations in France and four overseas (Mauritius, Reunion, Madagascar) going one step forward in 2012 by partnering with Saint-Gobain. The redemption half the Eurofloat plant in Salaise-sur-Sanne (38) seals the covenant in terms of production.

For Eurois from nothing 38 years ago, the act is not trivial. "A marriage between people of the CAC 40 and a peasant's been a shock! "Jokes the contractor who last year received the prize" heart stroke "of the jury of the 25th Victoires Autodidactes. "Today, we are the only independent in France to launch an oven. Groups have already done, but not peasants "proudly insists, Pierre Riou, head of a company that generated € 165 million in turnover in 2015.

If these days are historic for Riou Glass, this also is investment that represents this new oven: € 26 million. They are in addition to € 50 million for the purchase of half of the plant, partly with the help of the Public Investment Bank. "I had the audacity to do so, I found the money," said Pierre Riou who claims to have perpetuated this site. "Employees [some 200 people, Editor's note] were skeptical. There was always a question mark over the future of the plant. "

If everything goes as agreed, Eurofloat proceed with the ignition on April 28, for a first glass poured on 19 May.

A project more in assets of this insatiable entrepreneur who does not stop there. "There is much to do in the United States and Canada," the boss slips 63 years. It opened, there is still a month using a company laying in Boulleville involved throughout France to help customers put large volumes. More no area is untouched by Riou Glass

Africaver, an investment in automotive glass.

Created thanks to the spin of the Enava in 1997, the company Africaver think about setting up a production unit in the west of the country to approach the future automotive division.

Located in the industrial area of Ouled Salah (Taher, Jijel), the Spa Africaver economic public company seriously considering settling in joint venture with a French company in Oran to enjoy the setting Place the automotive cluster in the region and provide automotive glass to the various plants that will take up residence there.

This choice is also explained by the desire of both partners to approach the free zones of Oujda but also Spain and its plants, to enjoy a cheaper cost than transfer of eastern countries export more than being a necessary objective, as the representative of the French company, met at the seminar on subcontracting.

CHEMICAL TEMPERING BECOMES ESSENTIAL IN THE FOLLOWING SITUATIONS:

- When thickness of glass is inferior to 2,5mm. Under this thickness it is very difficult and nearly impracticable to thermal temper.

- In case of glasses with very complex bending or dimensional characteristics that cannot be

tempered with thermal equipment.

- Necessity of mechanical resistance superior to the ones obtainable with thermal tempering, in case of special industrial or architectural application.

- Necessity of impact resistance superior to the one obtainable with traditional thermal tempering.

- Necessity to obtain, in addition to mechanical resistance, high optical requirement and total absence of glass surface deformation for industrial and motor application.

To contact us. This e-mail address is being protected from spambots. You need JavaScript enabled to view it

Flat glass newsletter. January 2016

2 new records for Vedip, Italian wheels on Internet for flat glass processing machines

Vedip, the online sales site of Italian wheels for mirrors machinery broke 2 records in January . The number of orders received (+ 14%) and the total amount of orders received (Euros) (+ 9.5%). The average basket has fallen slightly to 453 Euros

Elumatec

The company elumatec AG occupies the leading position in the manufacture of machines for machining aluminum profiles, plastic and steel. The company covers with a complete range of products, the entire spectrum of users, from small enterprise to industrial machining company profiles. Custom machine concepts allow flexible and modular and individual industry solutions for all customer groups. Founded in 1928, the company operates from its headquarters in Mühlacker, in the Swabian region. It also has

subsidiaries and representations in more than 50 countries, representing a total workforce of 700 people and generating a turnover of nearly 120 million euros in 2014.

Closing liquidation A.M.F. Workshop Sarl Miroiterie Faure. Toulouse, France.

A temporary deferment was granted by the court Tribunal De Commerce De Toulouse AMF Workshop Faure Sarl Miroiterie located in Toulouse. The RCS number of this case is the judgment 347463192. The closing of insufficient assets is published.

Baku Glass 2016

For the first time, international experts, solution providers, product suppliers, professionals and decision makers from the glass manufacturing and processing industries of the Caucasus will have the chance to meet in the main city of Azerbaijan for a two-day event exclusively dedicated to doing business and discussing the latest technical advances in the glass sector. Baku Glass 2016 (1th – 2nd March, Holiday Inn Hotel) is the glass industry event for the Caucasus and Caspian Sea Region.

Africaver, an investment in automotive glass.

Created thanks to the spin of the Enava in 1997, the company Africaver think about setting up a production unit in the west of the country to approach the future automotive division.

Located in the industrial area of Ouled Salah (Taher, Jijel), the Spa Africaver economic public company seriously considering settling in joint venture with a French company in Oran to enjoy the setting Place the automotive cluster in the region and provide automotive glass to the various plants that will take up residence there.

This choice is also explained by the desire of both partners to approach the free zones of Oujda but also Spain and its plants, to enjoy a cheaper cost than transfer of eastern countries

Change at the top of BV Glas – Dr. Frank Heinricht takes over Presidency for glasstec 2016, Dusseldorf

The Federal Association of the Glass Industry (Bundesverband Glasindustrie e.V.) has elected Dr. Frank Heinricht, up to now Chairman of the Board at Schott AG, for its new president. This means he will also take charge as president for glasstec 2016. Presidency for this, the world’s leading trade fair alternates in line with its two-year cycle of glasstec between the Bundesverband Glasindustrie e.V. (BV Glas) and the Federal Association of Glazier Trades (BIV). Both organisations alongside the VDMA, the German Engineering Industry Federation (Verband Deutscher Maschinen- und Anlagenbauer e.V.). serve as conceptual sponsor of glasstec.

2 building fairs in Africa in 2016

2 Building fairs will be held in Africa (Kenya and Tanzania) in the summer of 2016.

Build Expoa Kenya

From 4 to 6 June 2016

Nairobi Keynya

Tanzania Build Expo

Dar Es Salaam. Tanzania

From 2 to 4 Jul 2016

Sharpening on straight grinders, bevelling, CN ...

Why is it essential to sharpen directly on your machine diamond grinding wheels and drills you use?

The active portion of the diamond tool mounted on the machine consists of diamond grains which are trapped within a binder. In contact with glass surface diamond grains are broken by lapping the glass. This requires the tool to be effective there permanently diamond grains that outcrop the binder.

It can happen for various reasons it did not sufficiently diamond surface of the grinding wheel or drills (for example, because the binder does not wear properly). In this case it must pass an abrasive stone surface of the tool (when running) to use the binder and slightly re-appear on the surface of diamond grains sufficiently active.

Please note there are several types of grinding wheels as a function of the sharpening tool (grindstone binder metal, resin, diamond drills ...)

For more information you can call us ![]() 00 33 783 39 43 34

00 33 783 39 43 34![]() 00 33 783 39 43 34 or have a look on Vedip00 33 783 39 43 34

00 33 783 39 43 34 or have a look on Vedip00 33 783 39 43 34

Bluetooth glass enclosure Sony

Life With Space UX, Sony wants to demonstrate that it is possible to design a hyper connected housing, where technology is everywhere, without being aggressive. The enclosure that the company present at CES abounds in this sense: it is a kind of lantern with LED inside that hides a Bluetooth speaker.

This is the glass that makes pregnant Office, and the result is quite impressive.

Sony expects to sell this Bluetooth speaker like no other in the spring, but remained evasive on some points. Autonomy is particularly unknown, as is the price. The product is clearly not cheap and should be produced in a small number of copies, Sony's aim is above all gradually start marketing which were previously only futuristic concepts. But the promise, however, proves interesting.

New offer aluminum Fire safety by Technal.

To meet fire regulations, which requires that public buildings and collective dwellings are equipped with systems protecting persons and property during any outbreak of fire, TECHNAL launches new PYROAL OFFER SAFETY FIRE. This technical solution enables aluminum to compartmentalize the spread of flames and smoke, and enhance heat resistance. It consists of a set door and glass wall, totally waterproof thanks to: - an intumescent seal around the windows and in the grooves of profiles - holding clips fastened with screws to the profiles. Certified * "fire safety" according to standards NF EN 1634 and EN 13501, it has three levels of classification: E30, ensuring a tight seal combustion gases, smoke and flames for 30 minutes, EI30, for its flame properties and thermal shield preventing the diffusion of heat for 30 minutes, EI60, sealing and insulation for 60 minutes. FIRE SAFETY SUPPLY PYROAL is tested by the approved laboratory EFECTIS fire by both sides in the direction of the fire. Five PV, two of which being drafted, guarantee its performance.

Agreement in the automotive glass from Saint Gobain and Corning

Saint-Gobain announced Monday the creation of a new joint venture with the American Corning to produce lightweight glass for the automotive market.

The French group says its Sekurit subsidiary signed an agreement laying the foundations of a joint venture equally owned.

The agreement provides in particular for the construction of new production units to meet the demand of the global automotive market.

The 'joint venture' is supposed to combine the glass Gorilla Glass' ultra Corning technology for automotive glass Sekurit to deliver innovations presented as' revolutionary '.

Selling Elumatec

Elumatec has been bought by the Italian company already has the Cifin Emmegi and KERAGLASS companies.

Elumatec, specializing in aluminum processing machines was forced into bankruptcy in the second half of 2013

Emmegi Elumatec and will have in the future, between them, six production units, five in Europe and Asia.

Cifin thus increases its production capacity since Emmegi now has between 6 and Elumatec plants.

The elumatec group achieved in 2014 nearly 120 million euros in turnover with over 700 employees.

Besides the head office and Mühlhacker production site in Germany Elumatec has a sales and production facility in Eastern Europe and over 30 sales subsidiaries and a sales and service network formed by many agents in over 50 countries.

Tribute glass sculpture.

The plastic Michel Stefanini, has created "A slight lull, work in glass memorial to commemorate the centenary of the disaster of the Belgian magazine, Gold Factory, Gonfreville l'Orcher, inaugurated December 15, 2015, in the presence of Vincent Mertens de Wilmars, Belgian Ambassador Hubert Dejean of Batie, Mayor of Sainte-Adresse, descendants of Count Broqueville, prime minister during the war of 14-18, and Jean-Paul Lecoq, Mayor of Gonfreville the Orcher.

In this glass embodiment, the plastic surgeon involved children of Mayville neighborhood, who have offered their impressions and 110 110 words for peace, collected during an in situ residence. Their marks and their words were inscribed on the windows pieces of sculpture.

The Municipality of Gonfreville l'Orcher honors the memory of the 109 victims and 1500 injured due to the explosion of the Belgian magazine "Gold Factory" this commemorative work, is the symbol of this disaster. But, beyond this injury, the city also wants to support through this embodiment, the culture of peace.

The artistic monument in the present and transmit to future generations the essential duty of memory in this regard and strongly mark the notion of appeasement, essential to the peace effort.

Four triangular elements, anchored on a concrete base, facing two by two. They evoke the power of the explosion of the arms factory in his elevation.

Two elements inclined toward the center of the memorial, symbolizing the direct victims of the explosion, they withdrew towards themselves with the duty of remembrance and recollection.

In addition and in contrast, the other two rooms open canopies and face, they carry a multitude of colorful prints and collection of words in the direction of peace. They are the hope for peace, and the necessary need openness of our contemporary societies.

According to the apparent movement of the sun, the color transmitted or reflected by the glass elements rest on all structures and linking recorded history that moving.

The building market could stabilize in 2016 in France.

The activity of the building industry (including markets of mirrors and marble) in France could stabilize this year, which would end a "continuous slump since 2012," said Thursday the Confederation of Crafts and small construction companies (Capeb).

With a decline of 2% in volume last year, reduced to -1% last quarter, 2015 "ends with less degradation of the activity of the building crafts," announced during a Capeb press conference.

However, this is the fourth annual decline of activity in the sector, which lost another 15,000 jobs last year, lamented Patrick Liébus, president of Capeb.

"Fortunately, the 2016 outlook is less dramatic, thanks to devices for the energy performance of new and accessibility of the built," he has said.

If it is "hard to be optimistic" vis-à-vis 2016, for Capeb, it's a little more confidence, building on "a change in volume of 0-1%".

Indeed, a "less degradation in new markets and the energy renovation and accessibility, should create more favorable prospects", which would "stop the continuous slump since 2012".

For Capeb, "speak of real recovery is premature, however, while the unfair competition and lack of consumer confidence ostensibly inhibit the growth of the activity of the building crafts."

In the fourth quarter 2015, the activity in the nine still yielded 2.5% (against 5% in Q3), while it remained sluggish in eco-renovation (against -1%).